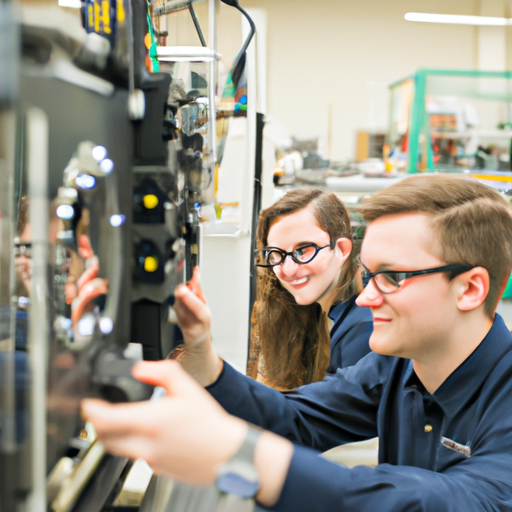

In the rapidly evolving world of manufacturing, the concept of Digital Twins has emerged as a revolutionary technology that drives Industry 4.0. A Digital Twin is a virtual replica of a physical asset, process, or system that enables real-time monitoring and analysis. This innovative approach is reshaping how manufacturers enhance operational efficiency and optimize production processes.

What are Digital Twins?

Digital Twins are sophisticated models that simulate physical entities in a digital environment. Through the integration of IoT sensors, machine learning, and data analytics, these models provide insights into every facet of the manufacturing process. By mirroring their physical counterparts, Digital Twins allow manufacturers to predict outcomes, diagnose issues, and implement solutions swiftly.

Benefits of Digital Twins in Manufacturing

- Enhanced Efficiency: Digital Twins enable manufacturers to fine-tune their operations by identifying bottlenecks and inefficiencies in real time.

- Predictive Maintenance: By analyzing data from machines and equipment, Digital Twins can forecast when maintenance is required, thus avoiding costly downtime.

- Product Development: Manufacturers can simulate products virtually, test them under various conditions, and modify designs to enhance performance before any physical production begins.

- Improved Decision Making: With access to real-time data and analytics, decision-makers can respond more quickly and accurately to changes in production strategies.

Implementation Challenges

While the benefits of Digital Twins are clear, implementing this technology comes with its own set of challenges. Manufacturers must invest in data security, employee training, and seamless integration of new technologies with existing systems. Additionally, scalability can be a concern as companies grow and their needs evolve.

Conclusion

The adoption of Digital Twins in manufacturing is no longer a futuristic concept; it is happening here and now. As manufacturers strive for maximum efficiency and competitiveness in a rapidly changing market, embracing Digital Twin technology is crucial for sustainable growth and innovation.

By leveraging this advanced technology, manufacturers can unlock a new level of operational excellence and pave the way for a smarter and more efficient manufacturing ecosystem.

For more information about how Digital Twins are revolutionizing the manufacturing landscape, stay tuned to our blog for the latest updates and insights.