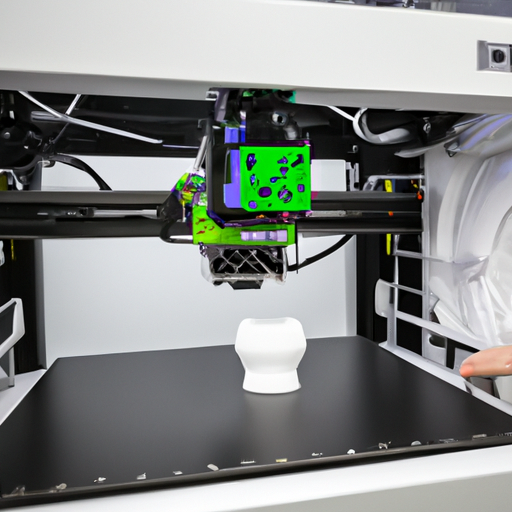

In recent years, 3D printing, also known as additive manufacturing, has emerged as a transformative technology within the manufacturing sector. This innovative approach allows for the creation of complex structures that traditional manufacturing methods struggle to achieve. In this blog post, we will explore the significant impact of 3D printing on manufacturing and how it is reshaping the industry.

1. Enhanced Prototyping Speed and Precision

One of the most remarkable advantages of 3D printing in manufacturing is the speed at which prototypes can be developed. Traditional prototyping methods can take weeks or even months, whereas 3D printing allows manufacturers to create functional models within days, if not hours. This rapid production not only saves time but also enables manufacturers to test and iterate their designs with unmatched precision, ultimately leading to better and more tailored products.

2. Reducing Waste and Costs

3D printing is inherently more sustainable than conventional manufacturing methods. Traditional techniques often involve cutting materials down to size, leading to a significant amount of waste. With 3D printing, materials are added layer by layer, which significantly reduces waste. Furthermore, the ability to produce complex parts on-demand minimizes the need for large inventories, thereby reducing overhead costs and streamlining the supply chain.

3. Customization and Personalization

In today’s market, consumers are increasingly seeking personalized products. 3D printing excels in customization, as manufacturers can easily adjust designs to meet individual needs without incurring substantial additional costs. This ability to personalize products opens up new avenues for businesses, greatly enhancing customer satisfaction and loyalty.

4. Disrupting Traditional Manufacturing Processes

As 3D printing technology continues to evolve, its potential to disrupt traditional manufacturing processes becomes even more apparent. Industries such as aerospace, automotive, and healthcare are already leveraging 3D printing to create lighter, stronger components, thus enhancing overall efficiency and performance.

5. Future Implications

The future of 3D printing in manufacturing looks promising. As technology advances, we can expect to see broader adoption of additive manufacturing, innovations in materials, and even the integration of artificial intelligence to optimize design and production processes. Manufacturers who embrace these changes will be well-positioned to lead in their respective industries.

In conclusion, 3D printing is not just a trend; it is a revolutionary force that is setting a new standard for manufacturing. By enhancing prototyping, reducing costs, facilitating customization, and disrupting conventional practices, 3D printing is changing the face of the manufacturing industry for the better.

Stay tuned as we continue to explore the advancements and innovations in 3D printing and how they impact various sectors of the manufacturing landscape.