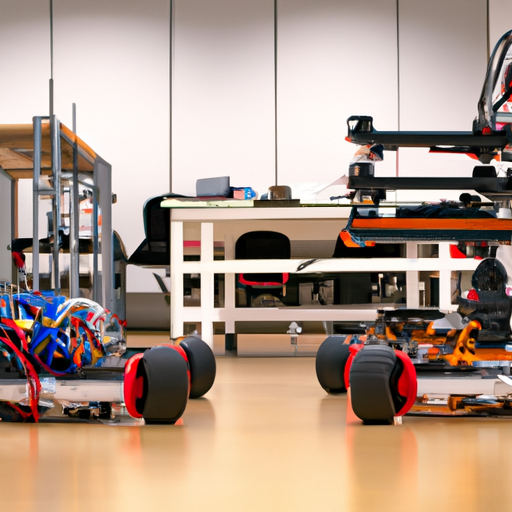

In recent years, the manufacturing landscape has undergone a significant transformation, driven by the rapid advancement of collaborative robotics, commonly known as cobots. These innovative machines are designed to work alongside humans in a shared workspace, enhancing productivity and safety.

What Are Collaborative Robots?

Collaborative robots are robotic systems specifically designed to interact with humans in a cooperative manner. Unlike traditional industrial robots, which operate in isolation, cobots are engineered to assist and augment human capabilities, making them ideal for a variety of applications, from assembly lines to complex machining tasks.

Benefits of Cobots in the Workplace

- Improved Productivity: Cobots can work alongside humans, taking over repetitive tasks while allowing workers to focus on more complex responsibilities. This synergy leads to higher efficiency and output.

- Enhanced Safety: Cobots come equipped with advanced sensors and safety features that allow them to detect human presence, reducing the risk of accidents in the workplace.

- Ease of Integration: Unlike their traditional counterparts, collaborative robots are typically easier to install and programming them requires less specialized knowledge, making them accessible for various sized companies.

- Cost-Effectiveness: Cobots are often less expensive than traditional robots, and their versatility means companies can deploy them for multiple tasks without the need for significant capital investment.

Applications of Collaborative Robotics

The versatility of cobots enables their application across numerous industries:

- Manufacturing: Cobots are being integrated into assembly lines to handle tasks like picking, packing, and quality control.

- Healthcare: In hospitals, cobots assist in tasks such as delivering medications, sterilizing tools, and even performing surgical procedures with precision.

- Agriculture: Cobots are used in precision farming, helping with planting, watering, and harvesting crops efficiently.

Future Trends in Collaborative Robotics

The future of collaborative robotics looks promising as advancements in AI and machine learning continue to enhance their capabilities. Key trends include:

- Increased Autonomy: Future cobots will be equipped with advanced AI algorithms allowing them to make more autonomous decisions, improving workflow and adaptability.

- Human-Robot Collaboration: As technology evolves, the collaboration between humans and robots is expected to become more seamless, leading to enhanced team dynamics in the workplace.

- Customization: More industries will demand cobots tailored to their specific needs, leading to greater customization options in robotic design and functionality.

Conclusion

As industries continue to embrace automation, collaborative robotics will play a pivotal role in shaping the future of work. With their ability to improve productivity and safety, cobots are destined to become an integral part of the modern workforce. Investing in this technology now ensures that businesses remain competitive in a rapidly evolving landscape.

Stay ahead of the curve by exploring how cobots can revolutionize your operations!